Supervised by Alex Thompson

During my first year at university I had the honor to complete an internship at the Bionics Institute under Alex Thompson!

I was at a biomedical techonology showcase. Long story short, I was plopped down in front of the Research Director Professor James Fallon and told "Well go on, pitch yourself!"

MIT Professor, Tim Dennison had inspired that day and I guess you miss 100% of the chances you don't take?

Thank you Alex for giving this green newbie a shot, it was an amazing experience to learn first hand from a person in the field and you are a huge part of why I am interested in biomeical engineering today.

Through hole soldering

Surface mount soldering

Assembled detailed and complex circuits using tweezers and a microscope!

Designed custom circuits for rapid prototyping

Designed custom footprints from scratch

Used Fusion360 to model custom parts

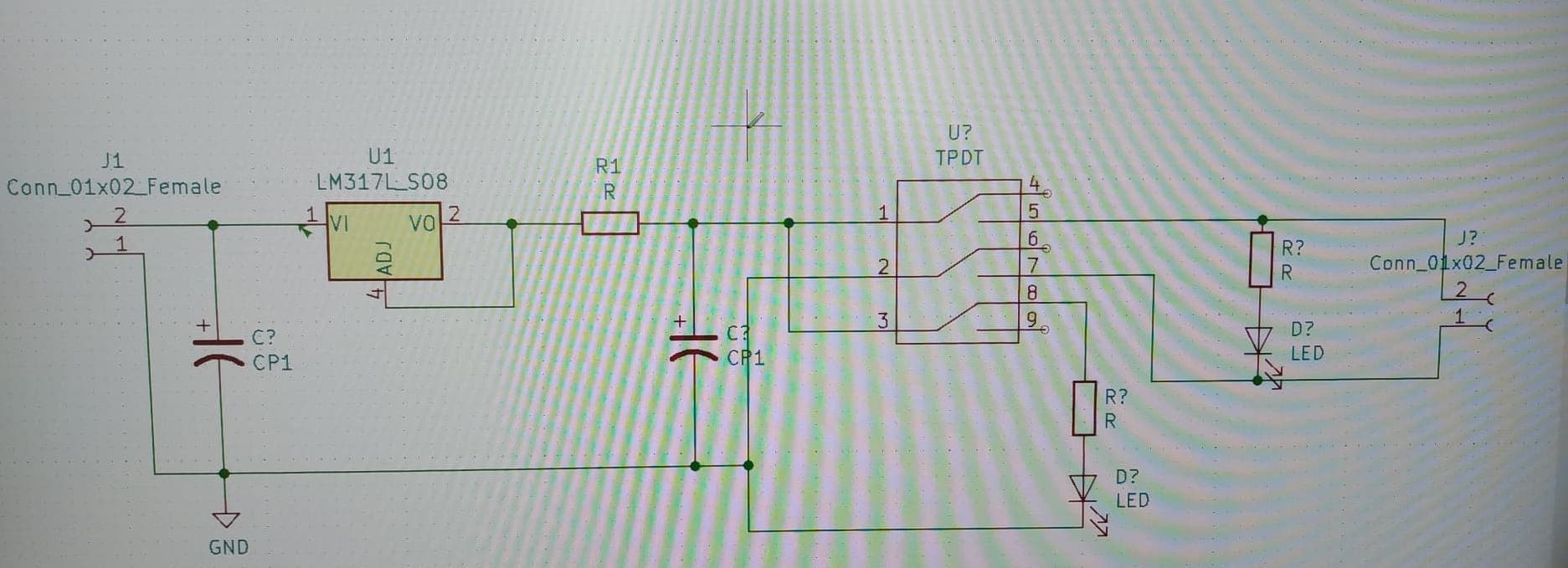

NiMH battery charger

"Hi Po, I would like a battery charger", naive me thought this would be easy... safe to say it was quite interesting.

This was my first KiCAD project and it involed designing a custom footprint and required me to learn about stuff like current smoothing, how different batteries charge, voltage dividers and how you could wire it in a special way to turn it into a constant current regulator.

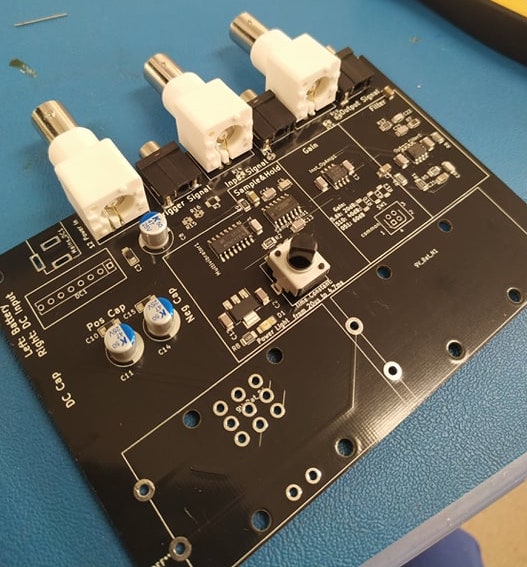

Detailed PCB assembly

This was my first project, assemble a signal processing unit with surface mount and through hole components.

It was a great project because it taught me patience, consistency and NOT to sneeze when doing something like this. I made multiple units of these and it was very satisfying looking at finished product.