Now there is a lot to consider when you need to attach something

to a racecare that aren't so obvious:

- Vibrations of the vehicle

- How the attachment is installed

- How the attachment is removed

- Will the attachment be able to withstand workshop garage 'oops I dropped my wrench' treatment?

- Will the vibrations of the car affect the quality of the signal in the sensor?

So long story short, I needed a design that will:

- Not be vibrated off the car or undo itself - be as minimal as possible in terms of the amount of parts

- Shelter the sensor such that it will be protected from dropped wrenches, but also have a way

for it to be mounted easily

- Have an accurate enough resolution to give a position based on the very fine angle of rotation

- Have a low hysteresis - the sensor will produce the same results after say one year since it will be mounted

very securely/rather permanently

- Good linearity for consistent results across a range

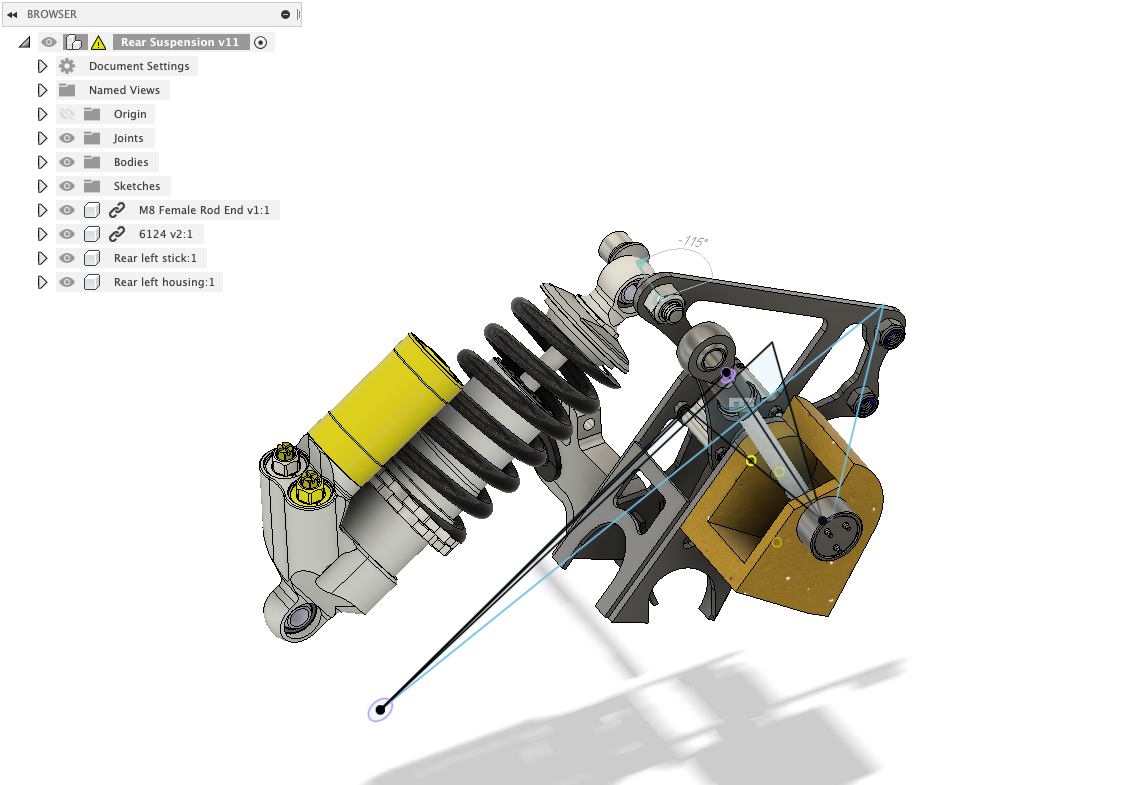

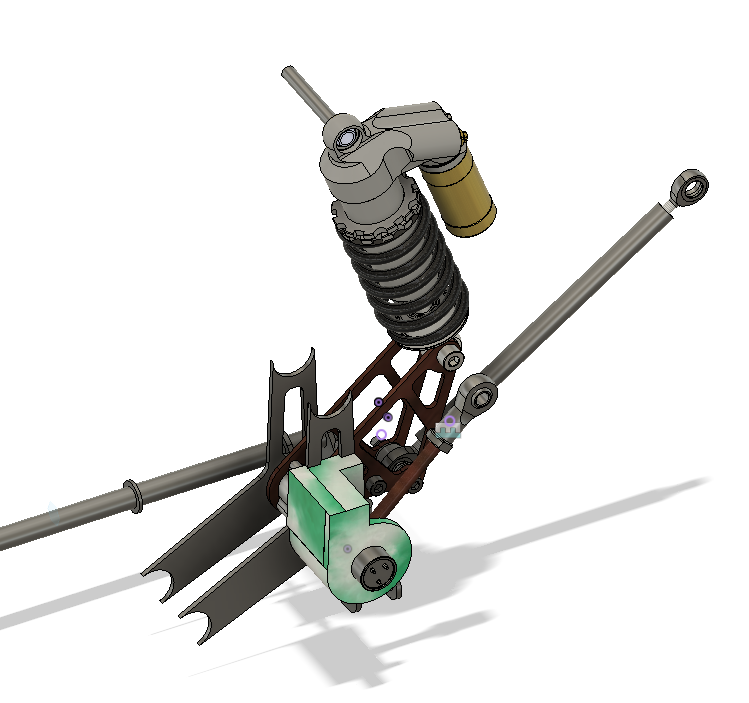

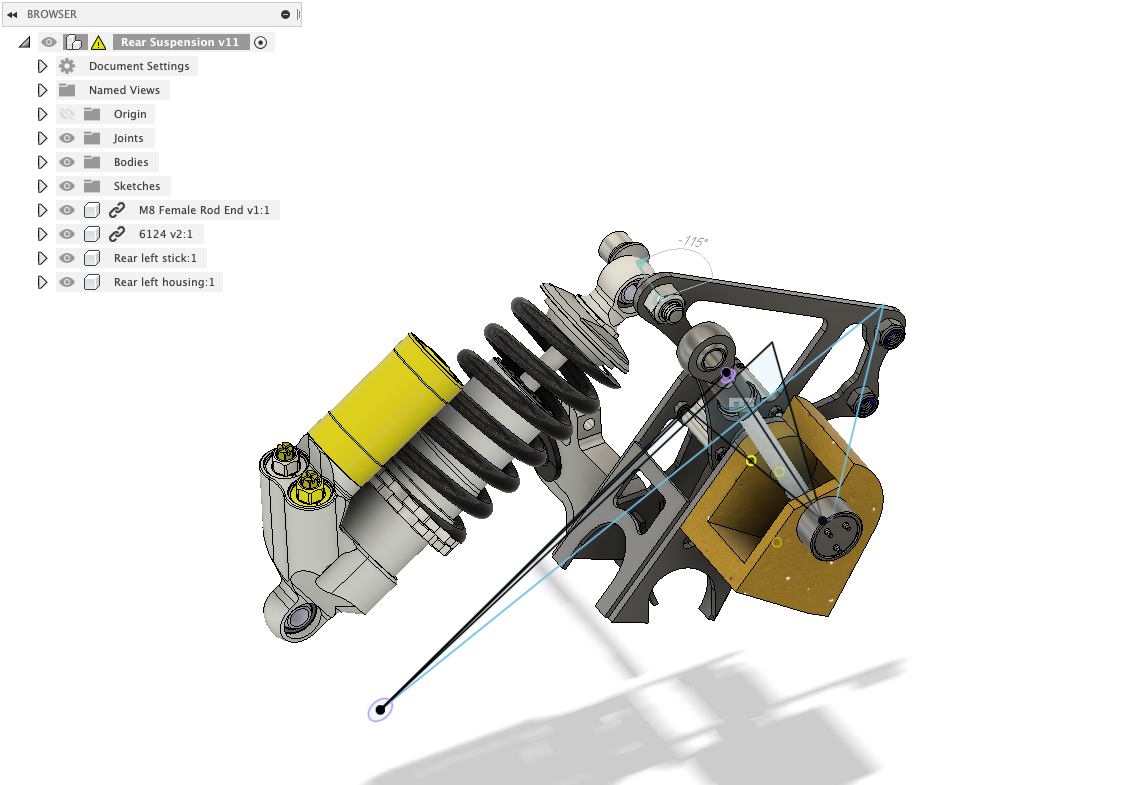

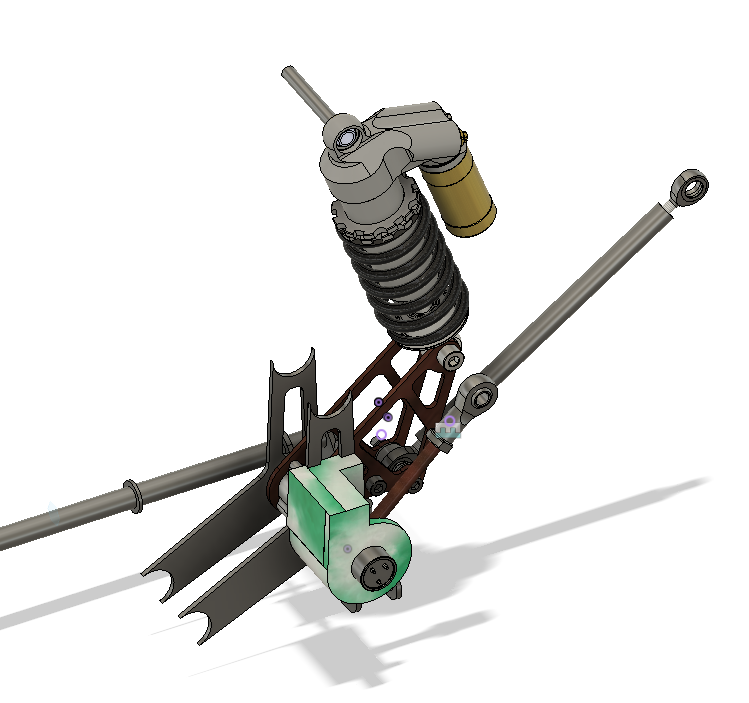

So after some kerfuffle if you will I present you this!

There are a few things to note about this design

- The mount is designed to slot into the chassis grooves to help create extra stability and prevent any wiggling

- The entire design can be 3D printed with ABS/PLA plastic, these are a lightweight and durable materials

and aren't heavy on manufacturing to ease the iteration phase

- There is a rod attached to the stem of a rotatory potentiometer that will rotate while the sensor

is fixed to the chassis

- It can measure up to 20cm in displacement from the suspension